Since 1940, Taiwan's shoemakers have gradually substituted PVC and PU for increasingly scarce and expensive natural leather. With their low prices, good elasticity and resistance to wear, vinyl shoes have become the most popular item on world footwear markets.

In line with the development of the plastics industry as a whole, many kinds of synthetic leather have been produced in Taiwan since 1962. By 1967, some 30 export factories have been established, and export value reached US$3 million. For the next few years, the export volume grew by 40 percent and value by 60 percent a year on the average.

Footwear manufacturers soon recovered from the effects of the energy crisis and worldwide recession which occurred in 1974. The year before, they exported a record 370 million pairs, and Taiwan became known as a leading producer of plastic shoes.

Protectionism on world markets started with the introduction of a quota system in the U.S. Canada, Australia, Britain and Ireland followed suit soon afterwards, and export growth received a severe setback.

Faced with these obstacles, Taiwan's makers decided that the only course of action open to them was to improve quality. As a result, the average unit price has risen from US$1.72 a pair in 1977 to US$2.71 in 1980. Although the volume of Taiwan's vinyl shoe exports has been static, the value has risen substantially. Statistics compiled by the Footwear Manufacturers' Association show that the value rose from US$651 million in 1977 to US$771 million in 1978 and US$945 million in 1979.

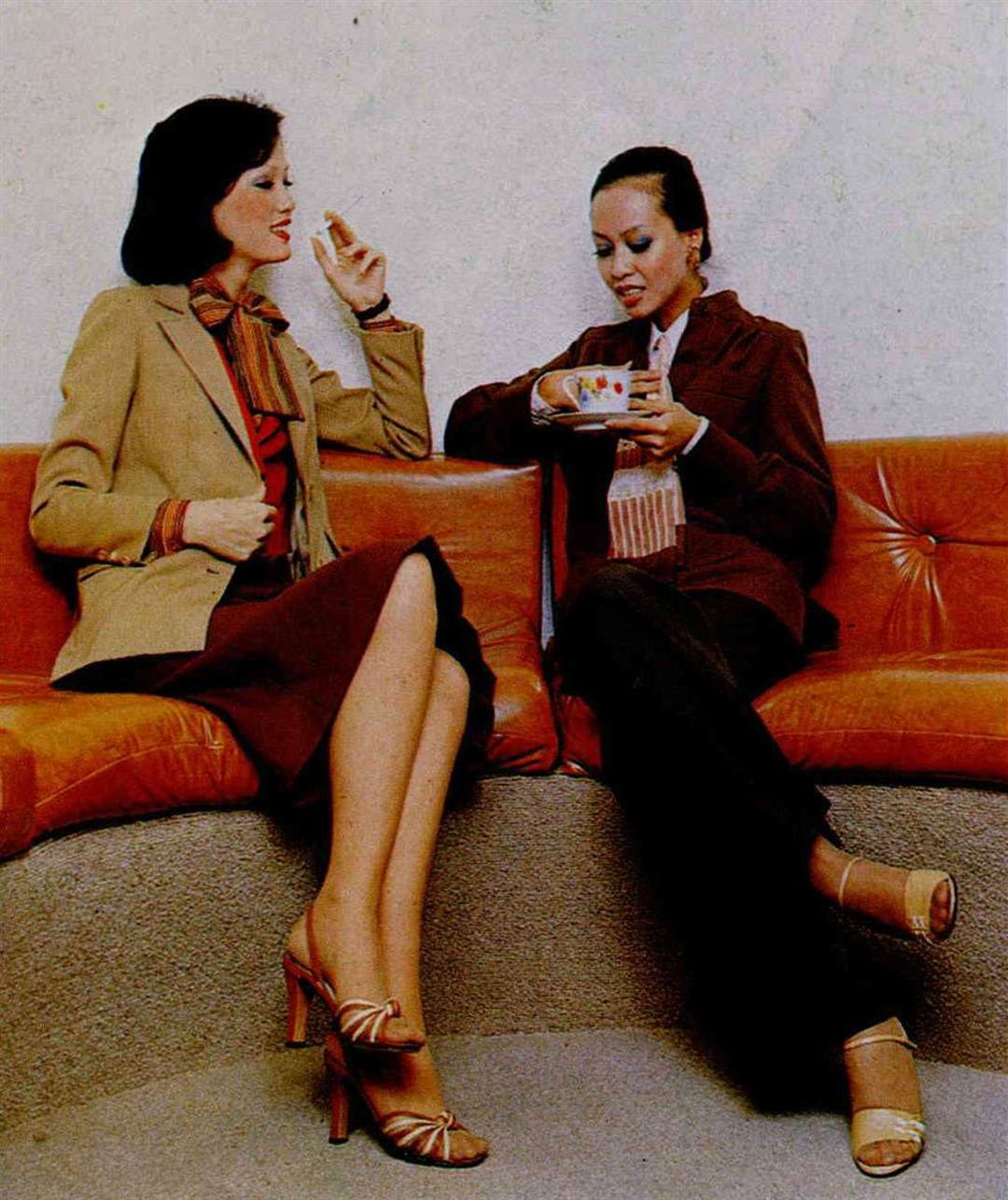

Items produced in Taiwan include sandals, slippers, dress shoes, loafers, high-heeled shoes, boots, work shoes, snowmobile boots, nursing shoes, children's shoes, infant shoes, beachcombers and sports shoes. Major markets are the U.S., a country for 65 percent of Taiwan's exports, followed by West Germany, Canada, Australia, France, Saudi Arabia, Britain, the Netherlands, Kuwait, Italy and Belgium.

The main reasons for the boom in vinyl shoe sales is the sufficient supply of synthetic leather and vinyl soles, and the unified export system adopted by manufacturers. The main functions of the Footwear Association are liaising among its 582 members, pursuing matters of common interest, improving techniques and undertaking research and development.

Although vinyl shoe exports are limited by quotas, the excellent quality and reasonable prices of Taiwan's products will keep the door to international markets open in the future.

[Picture Caption]

(1) Known as a leading producer of plastic shoes, Taiwan has manufactured a wide variety of products. Boots (2), slippers (3) and sandals (4) are the major export items.

Cutting (1) and quality control (3) in the shoe factory. (2) Modern sandals. (4) All kinds of sandals are made for export. (5) Sports shoes with plastic soles. (6) Shoe exhibition sponsored by the China External Trade Development Council.

are the major export items.

All kinds of sandals are made for export.

Sports shoes with plastic soles.

Shoe exhibition sponsored by the China External Trade Development Council.