Unrivaled:

Fifty Years of Reporting on Manufacturing in Taiwan

Cathy Teng / photos MOFA file photos / tr. by Phil Newell

December 2025

Taiwan’s textile industry boasts superior capabilities, with unseen cutting-edge technology embedded amidst apparently routine weaving. (photo by Lin Min-hsuan)

As the US calls for “reshoring of manufacturing,” global industrial chains are being redefined. In manufacturing, however, competition is not only about prices, but about national capabilities, technology, and trust. And one name has continued to resound throughout this worldwide competition—Taiwan.

Taiwan’s manufacturing base not only anchors the economy; it has forged a distinctive resilience—the ability to pivot quickly, stake out its niche, and participate in global supply chains as a trusted partner.

The early days

Flipping through old issues of Taiwan Panorama, which was founded in 1976 and has covered Taiwan’s development for half a century, one can see how the people of this island—faced with limited resources but filled with hope—have worked together with determination to seize every opportunity.

A 1978 report talked about how Taiwan’s umbrella industry surpassed that of Japan. One in 1979 pointed out that buttons, small as they are, could earn lots of foreign exchange for Taiwan. And in 1980, a story noted that exports of Taiwan’s vinyl shoe industry developed to such a level that some countries were imposing limits on Taiwanese products. Indeed, Taiwan became a “kingdom” for industries including furniture, toys, and hardware, and was known as the “export kingdom.”

Most early industries were labor-intensive, so transformation and upgrading was essential. In a 1980 story, “Jacks Raise Export Earnings,” the success of this product (i.e. the tools used to lift things such as cars) was shown to be a result of government-introduced standardization and quality controls. Since those days, manufacturing in Taiwan has moved from “quantity” to “quality.”

Baseball mitts, golf clubs, and electronic products were once representative Taiwan export products. (photos by Lin Min-hsuan)

The key role of industrial policy

Government strategic leadership was critical back in those days. In 1976, Taiwan Panorama published “The EPZs—Working for National Development,” noting that government-planned export processing zones, combining industrial parks with free trade zones, not only successfully attracted foreign investment, they expanded exports and injected powerful dynamism into the domestic economy.

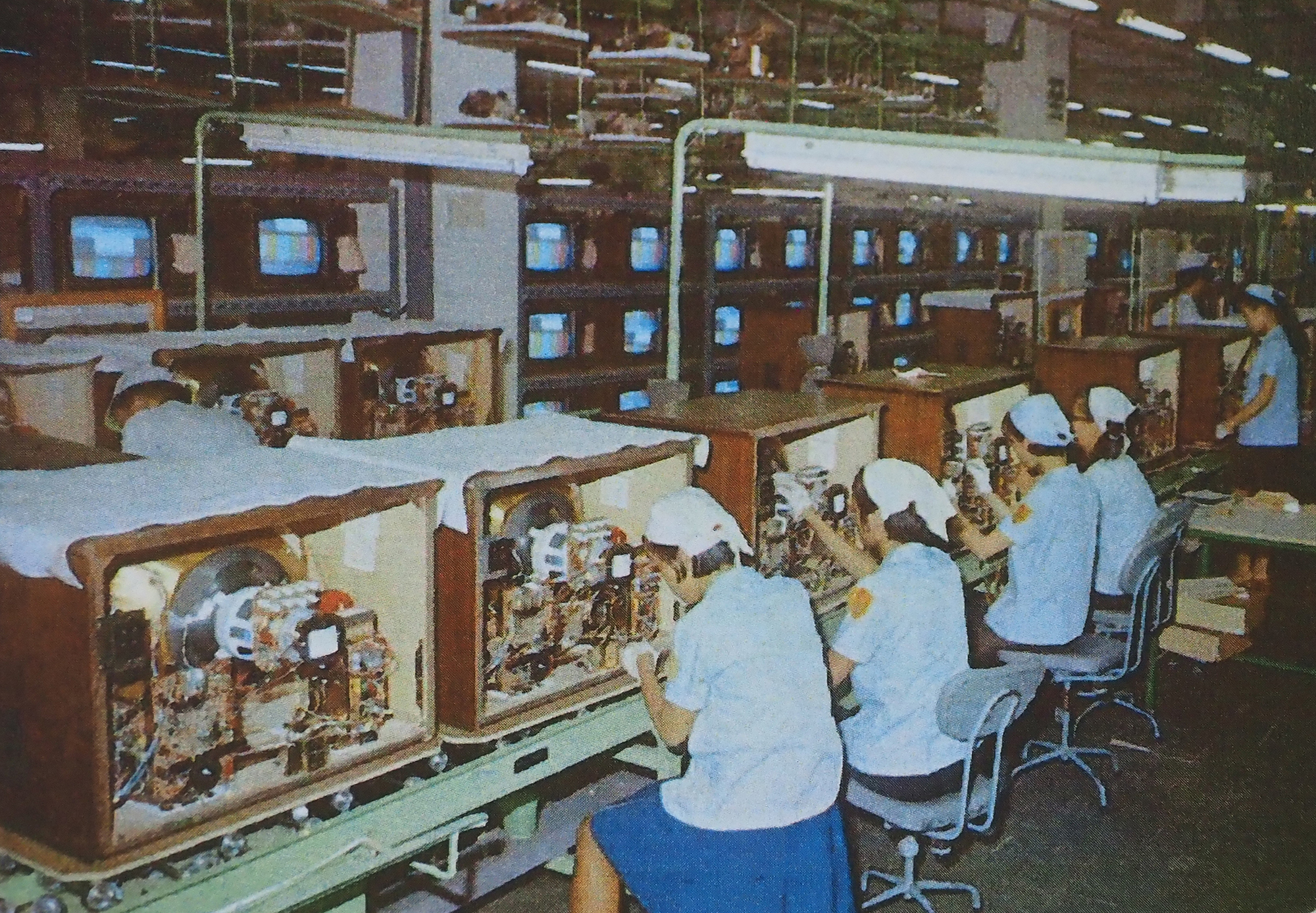

In that era of “export expansion,” many products for daily life, like electrical consumer goods, were made in the Kaohsiung EPZ and shipped out of the Port of Kaohsiung to the world. That was the starting point of “Made in Taiwan.”

In 2022, a follow-up found this zone rebranded as a “Technology Industrial Park,” with the focus shifting to upgrading, smart manufacturing, and sustainable innovation.

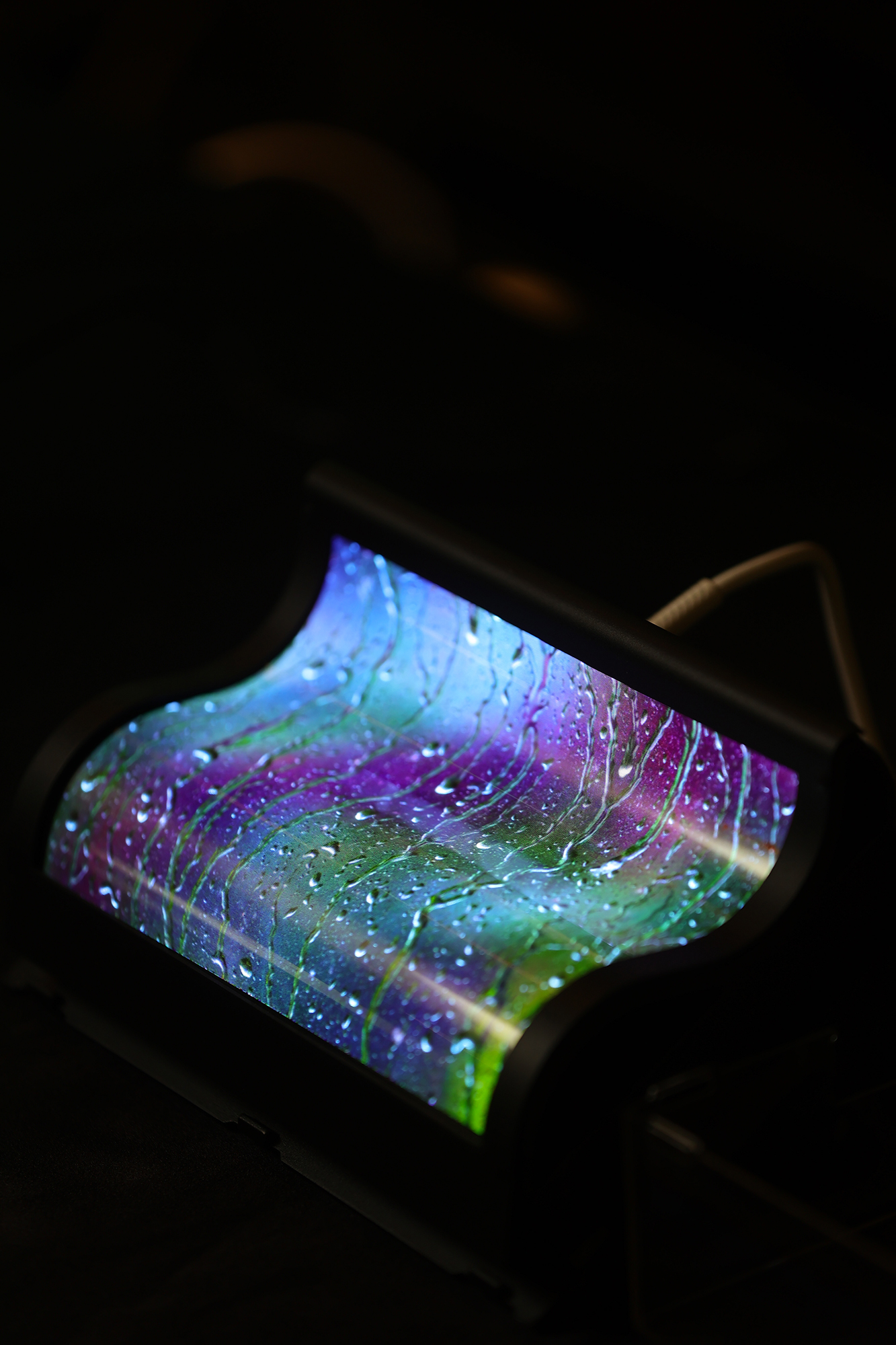

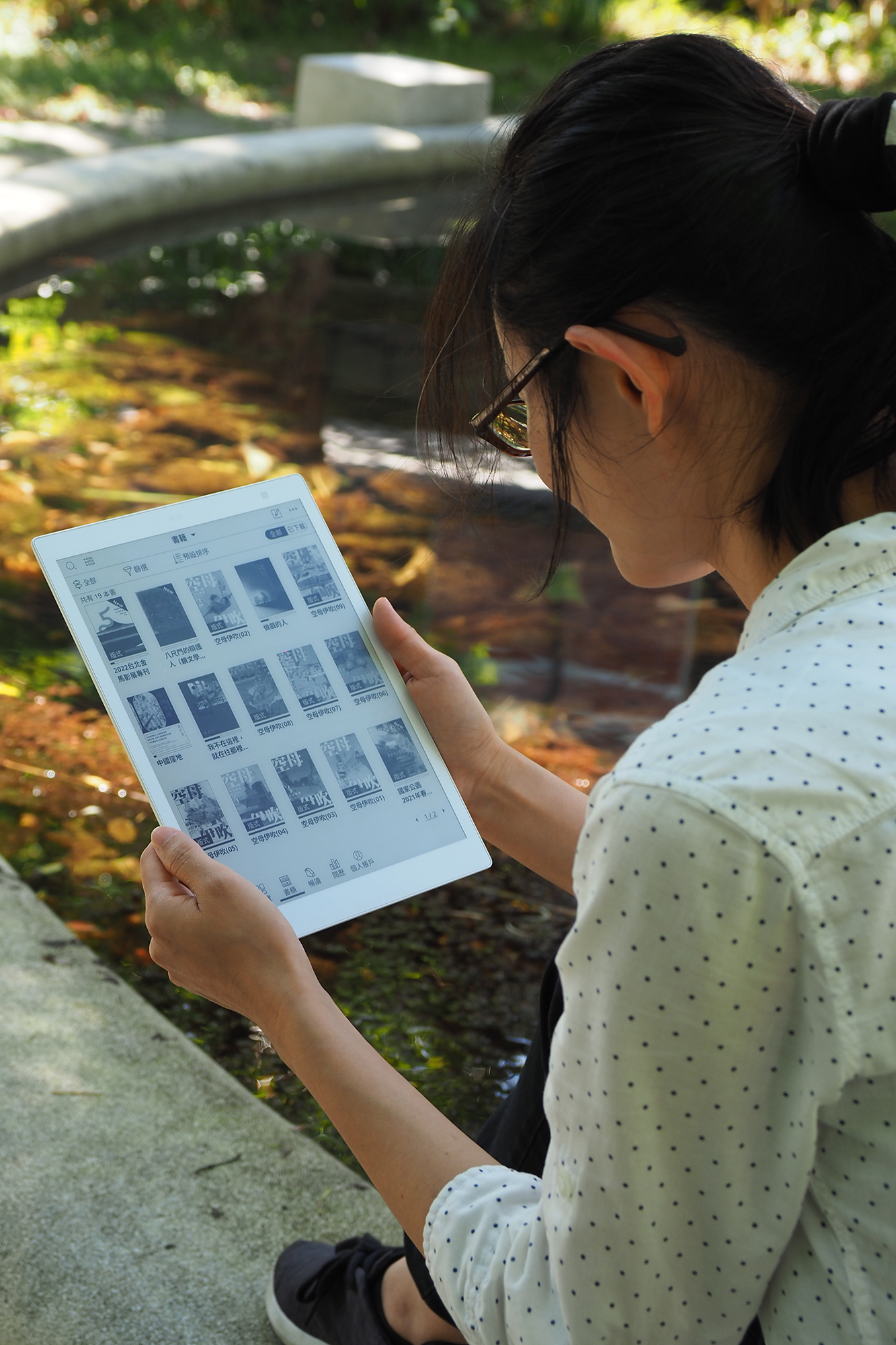

We have also tracked government institutions founded to promote industrial upgrading. For example, the Hsinchu Science Park is the cradle of high-precision industry. As early as 1978, Taiwan Panorama had an article called “Integrated Circuit Technology: A New ROC Success” at a time when the future Taiwan Semiconductor Manufacturing Company was still a branch of the Electronics Industry Research Center of the government-backed Industrial Technology Research Institute (ITRI). In 1980, Taiwan’s first IC firm, United Microelectronics, was spun out of ITRI. Later the display technology, panel, and e-paper industries likewise grew from that ecosystem.

Export Processing Zones were an integral part of Taiwan’s era of putting economic development ahead of everything else. (MOFA file photo)

photo by Kent Chuang

Taiwan’s small and medium-sized enterprises rely on creativity and quality as they display outstanding R&D capabilities and international competitiveness.

The evolution of Taiwan manufacturing

In the waves of globalization, Taiwan has not only not been washed away, it has ridden the crests to find its own unique positions. Two major industries, textiles and bicycles, have been models in this respect.

A 1983 report, “Taiwan’s Booming Textile Industry,” discussed the way that this industry had comprehensive integrated up- and midstream industrial chains, but was seen by some as a “sunset industry” because of competition from cheap labor abroad. However, it was even then reinventing itself to lay the groundwork for the future.

In the 21st century, the textile industry has exploited hi-tech R&D to change its fate. A 2018 article described how textile manufacturers in Tainan devised a way to use discarded fish scales to develop environmentally friendly fibers with good texture and functionality. In 2019 “A ‘Silicon Valley’ for Textiles” pointed out that 70% of functional fabric worldwide came from Taiwan. Such stories highlighted the astounding innovative capabilities of this industry.

The next wave was the birth of “smart clothing.” By this time attire had already evolved to being “wearable computers” capable of tracking the human heartbeat, pulse, mood, temperature, and stress. Articles in 2019 and 2022 underscored how Taiwan’s textile industry moved beyond traditional manufacturing to being an innovation platform combining technology and daily life.

Meanwhile, bicycles, which are today equated with sustainability, is one of the industries of which Taiwan can be most proud. Taiwan Panorama began following this industry in 1983, serving as a witness to the transformation of Taiwan from OEM manufacturing to being the “bicycle kingdom” and a center of global hi-end bicycle production. As part of this transition, countless parts manufacturers in the industrial chain have, through cooperation and competition, built unique networks.

In our October, 2023 issue we ran a cover story called “Interpreting the Bicycle Kingdom.” It discussed how Taiwan’s bicycle industry has adapted to global competition, described in detail the admirable achievements of cutting-edge parts makers, and talked about the next generation of sustainable smart e-bikes.

Taiwan Panorama has published multiple cover stories on Taiwan’s “hidden champions.” (MOFA file photo)

Taiwan firms have been part of the development of the e-paper industry from the start, and Taiwan is playing an influential role in building a sustainable future.

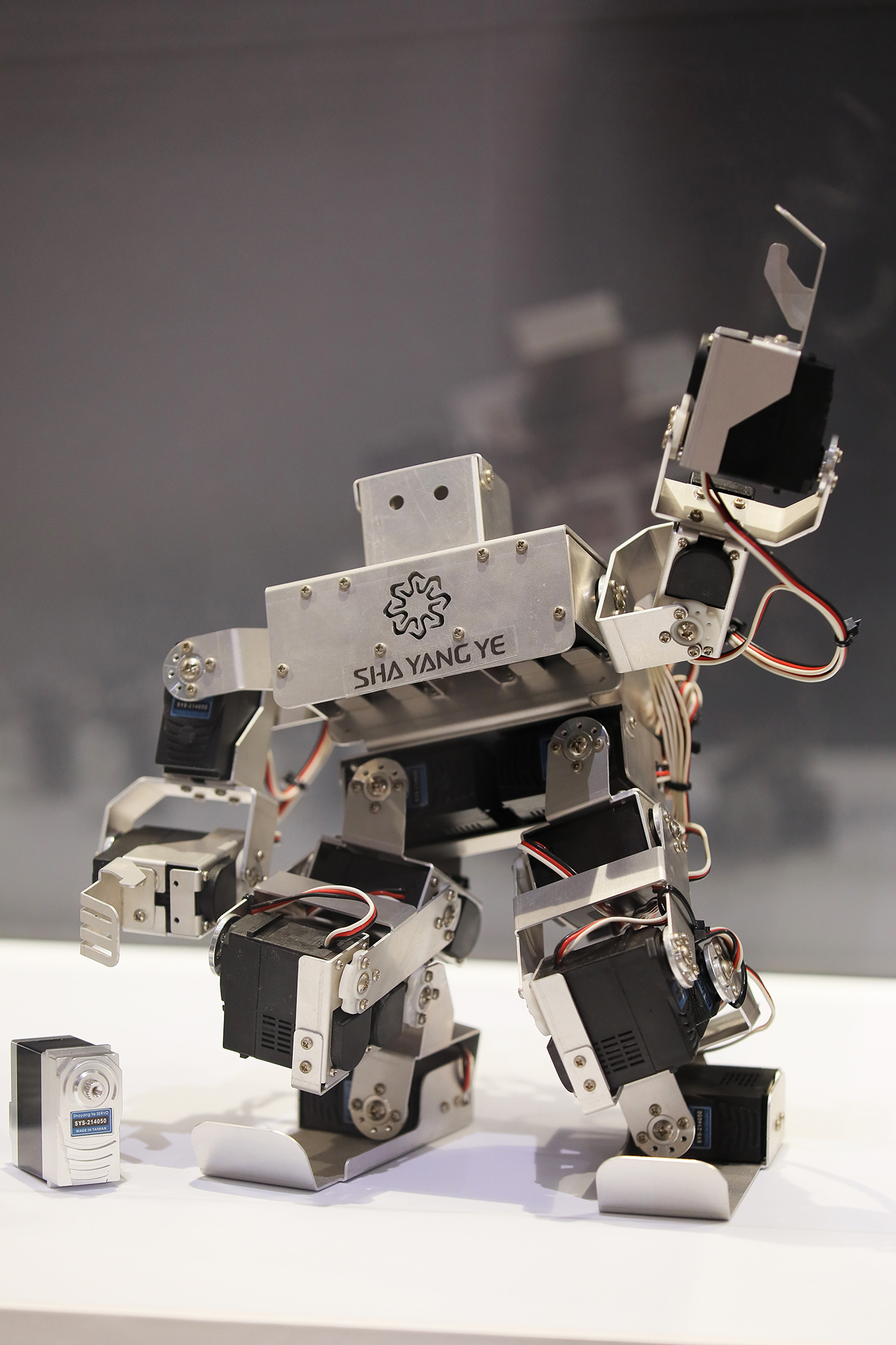

“Give me a gear to turn, and I will move the world.” This is the motto of Sha Yang Ye, which symbolizes the way that Taiwan’s small and medium-sized enterprises use robust technologies and a spirit of innovation to “make the world go round.”

Partner to the world

In 1981 the German management scholar Hermann Simon proposed the idea of “hidden champions”—small and medium sized enterprises that dominate global niches. In Taiwan they are often likened to Germany’s “Mittelstand” firms.

Taiwan Panorama returned to this theme in 2014, 2021, and 2023. Articles described hidden champions with low profiles but high levels of expertise, including Elan Microelectronics, Merida, Sheico, LCY Chemical, Kinik, Sha Yang Ye, Mega Master, and Eternal Materials. Every report discussed how company leaders transcended obstacles to realize excellence in their respective fields.

In addition, these stories also reveal a customer-centric ethos. Taking a 2021 report on Taiwan’s fasteners industry for example, an interviewee told us: “We are involved with all the innovations happening in the world. You have your imagination, and we have our execution. If a customer can give us a drawing, we’ll help them bring their idea to life.”

In page after page of stories, Taiwan Panorama has not only recorded the evolution of Taiwan’s legendary manufacturing sector, but also the perseverance, creativity, and resilience of this island’s people. These reports have showcased the integrity and dedication of Taiwanese in the pursuit of collective prosperity and partnership with the world.

The many hidden champions of Taiwan’s bicycle industry have adopted countless innovations to make the island into the bastion of high-end bike production that it is today. (photo by Kent Chuang)