Last year the R.O.C.'s textile exports came to US$ 5,000 million, about one fourth of the ROC's total exports. The industry's importance can also be seen from the fact that it employs 400,000 people.

Because of the importance of the industry, any sign of disturbance therein invites widespread concern from the nation's people. In recent years the world's economy has not been robust, newly-developed nations with cheap labor have been competing in the marketplace, and many countries have been practicing protectionism and limiting imports of ROC textiles and finished clothing. Therefore, some people call textiles a "sunset industry".

Is textile really a sunset industry? People still want to wear clothes, and today's people are even more particular than before about clothing. They don't just want to cover their bodies from the elements but also to express themselves in clothing. So as living standards increase, the textile industry is going to be more promising. The industry has a strong base, so long as the industry people are not convention-bound and they emphasize research and development leading to high quality products. In this way they look forward to new prospects.

In 1949, the year of the Communist takeover of the Mainland, Taiwan's textile factories only had 20,000 or so spinning machines, and production was not sufficient to meet domestic demand. Today, there are more than 3,500,000 spinning machines in Free China. 80% of the production of the machines is exported; export earnings have reached U.S.$5,000 million and the ROC has become one of the three major centers of textile exports, the other two being Korea and Hong Kong.

For example a domestic textile factory with 50,000 spinning machines, ten years ago required more than 2,000 workers, five years ago a thousand workers; now it employs only 250 people. In the past, textile was a labor-intensive industry, and investment, processing and technology were limited, cheap labor being the main input. Now to build a 50,000 spindle plant takes an investment of more than NT$50,000,000; the industry is tending to become capital- and technology-intensive.

Taiwan's textile industry began in 1951. At that time the government wanted the ROC to change from being an agricultural society to an industrialized society. It provided every kind of assistance for the development of the textile industry. At the start, the products were for domestic consumption; exports began in 1956.

At that time the ROC took advantage of low labor costs to produce low-cost products, and sold them to the U.S.A., Canada and other developed countries. The opening of the market was entirely successful. In the ensuing years, with more and more processing of products, the industry became more and more developed.

In the 1960's, the finished-clothing industry arose; after 1971, following the advance of the chemical industry, the synthetic-fiber industry appeared, and the domestic industry's structure was completed. The textile industry can be analyzed as follows: upstream, the synthetic fiber industry; in midstream, the fabric industry; downstream, the finished-clothing industry.

The development of the synthetic-fiber industry benefited the ROC's textile industry by causing prices of raw materials to go down, quality of products to go up; while causing the industry to begin being concerned with technology. For example, Cotton is water-absorbent, and in clothes can absorb perspiration, making the wearer more comfortable. But cotton clothes do not dry easily. Blending cotton with synthetic fibers makes an easy-to-dry fabric. Pure wool wrinkles easily, but a wool blend can even be pressed conveniently at home, and its price is much lower than pure wool. Currently most fabrics are made of a blend of natural fibers such as cotton and wool, etc., and synthetic fibers.

The ROC's textile industry expanded most rapidly between 1966 and 1973. In 1973, the ROC's annual production of textile products exceeded US$1,300 million, representing about 30% of the country's total exports. But during that period of all-out investment, economies of scale, production efficiency, management, technology, etc., were all ignored. In 1973, the first oil shock occurred, and demand and prices for textile products plummeted while overhead increased, putting the industry under great stress. Only then did industry figures become aware of the dangers of blind expansion.

Nor was this the end of difficulties. Since the oil shock, the price of textile raw materials has skyrocketed, and meanwhile the people's living standards were rising, resulting in higher labor costs. The developed countries protected their domestic textile industries with import quotas. Moreover, the ROC had been concentrating on the low-priced market. As such less-developed areas as the Philippines, India and Mainland China took advantage of very low labor costs and local resources, the competition grew.

Besides competition from the outside, factories faced competition in the domestic market, where financial conditions were insecure, and companies engaged in desperate price-cutting. Under these "fighting within and without" conditions, by 1980 the market share of textile exports was declining, and some spoke of textiles as a sunset industry.

The Secretary of the Republic of China Textile Export Promotion Board, Mr. Keng denies that textiles are a sunset industry. He says, "This remark was first made by the Japanese. Since Japan wants to reduce the role of the textile industry, they coined this phrase. Nonetheless, Japan's textile industry hasn't declined, but remains one of Japan's major export industries."

The ROC is also finding that while it advances, other formerly undeveloped countries are making gains. Although Korea's industry began five years after the ROC's, it is catching up to it. How is this? Although the number of spinning machines in the two countries is roughly equal at 3,500,000 each, in 1971 the Korean government mandated the consolidation of factories, resulting in a current total of a score or so factories in all Korea. By contrast, the ROC has more than 1,000 factories, averaging less than 10,000 spindles per factory. They just can't achieve economies of scale.

Previously, most factories would rapidly expand in good times, and get squeezed in bad times; very few were careful to invest profits in new equipment and other necessities for securing the company's prosperity. It takes a lot of investment to shift from cheap goods to higher-grade goods. The government has been encouraging companies to engage in more investment, use of technology and cooperative planning, but there is still the desire on the part of most industry figures to be their own bosses.

But in most recent days a new trend is emerging: direct cooperation between textile factories and finished-clothing factories. They cooperate in marketing to foreign countries. With diligent cooperation, the textile factories can have steady clients, and don't need again and again to drum up business abroad. The finished-clothing factories, with established suppliers cooperating, needn't worry about delays in deliveries, nor that the raw materials might be unreliable. If they detect any problem with the fabric, it can be quickly resolved. In such a relationship, both sides benefit.

An upstream textile company can cooperate with a downstream finished-clothing producer to develop new products. The textile maker can provide information and ideas and produce samples for the clothing maker's consideration.

In the future, the ROC's textile industry will develop in the direction of multi-stage processing, in order to raise the value added to each product. Therefore finished clothing will occupy an even greater share of the export market, and the finished-clothing and fabric industries will grow ever closer. Currently most clothing factories are small-scale, fabric plants are large by comparison, their capital is more plentiful and their information more up-to-date. This can help the finished-clothing industry grow. As the finished-clothing industry grows, the fabric producers will have a larger domestic market. That is why this multi-stage sort of cooperation emphasizing added value is considered the correct path for the ROC textile industry.

[Picture Caption]

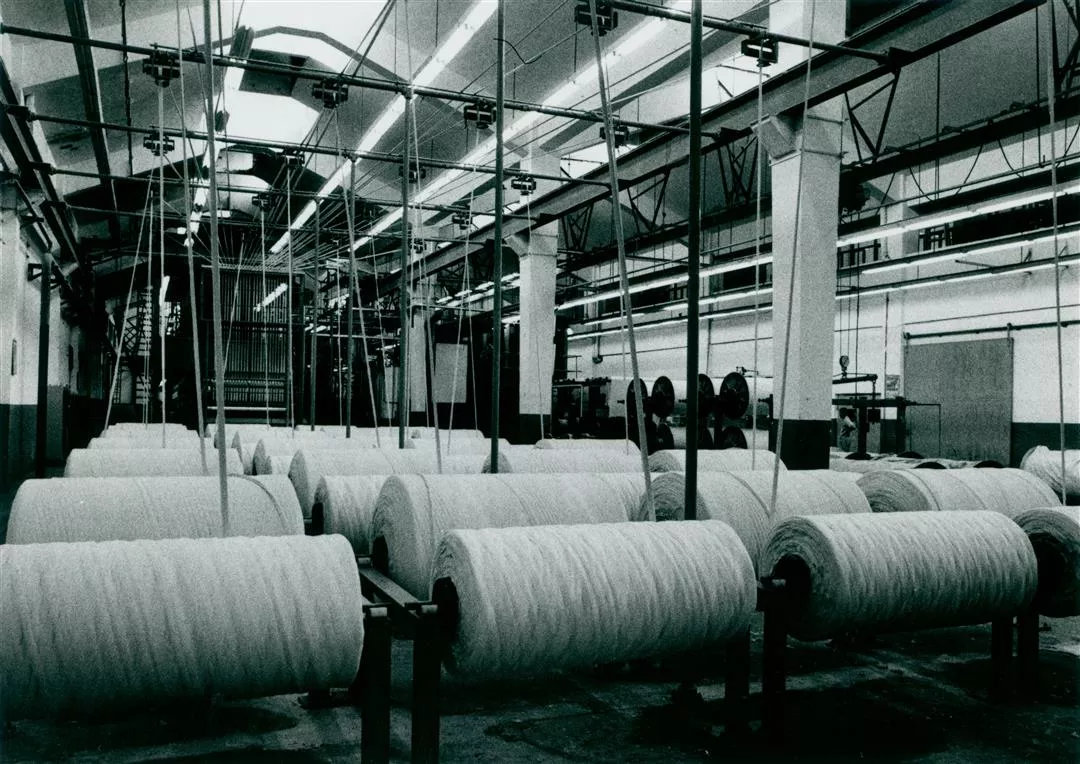

The industry is becoming technology-intensive.

1. Seaward Taichung Wool Textile Company's wood-washing machine, used to wash away foreign matter and excess oil from raw wool. 2. Seaward's new weaving machines imported from Switzerland are fully automated; one worker can operate six at once. 3. T'ai-yuan Textile's spherical warping device aids the work of making yarn.

Industry leaders still see a bright future. 4.5. Automation almost eliminates the need for human supervision.

T'ai-yuan's process for making colored denim.

The industry is becoming technology-intensive.

The industry is becoming technology-intensive.

The industry is becoming technology-intensive.

The industry is becoming technology-intensive.

1. Seaward Taichung Wool Textile Company's wood-washing machine, used to wash away foreign matter and excess oil from raw wool.

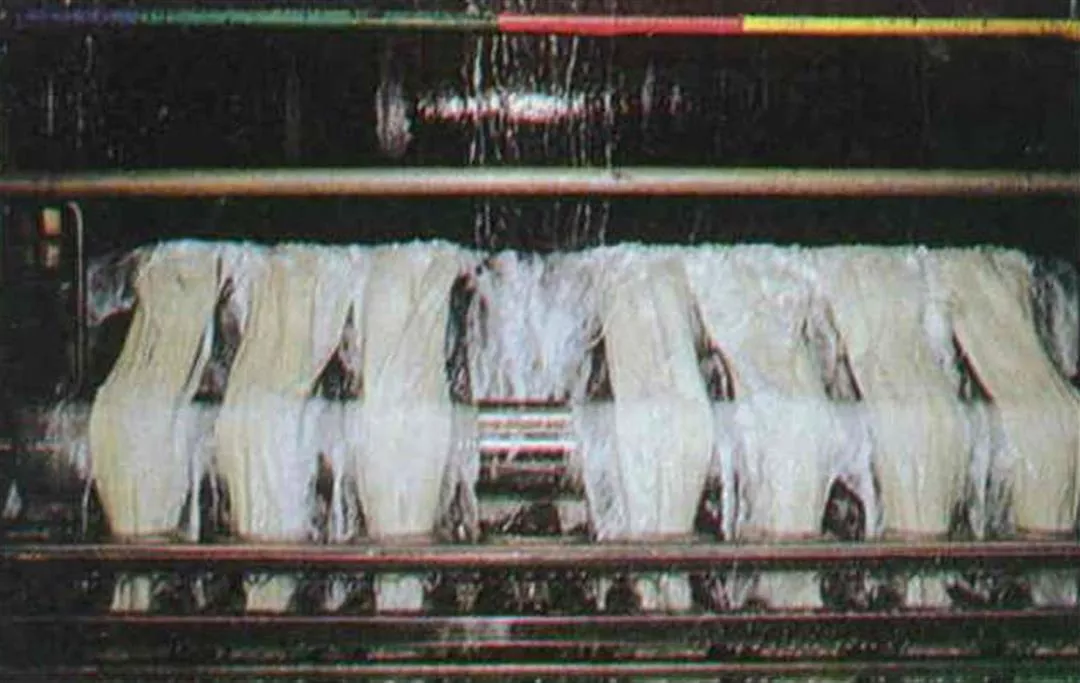

2. Seaward's new weaving machines imported from Switzerland are fully automated; one worker can operate six at once.

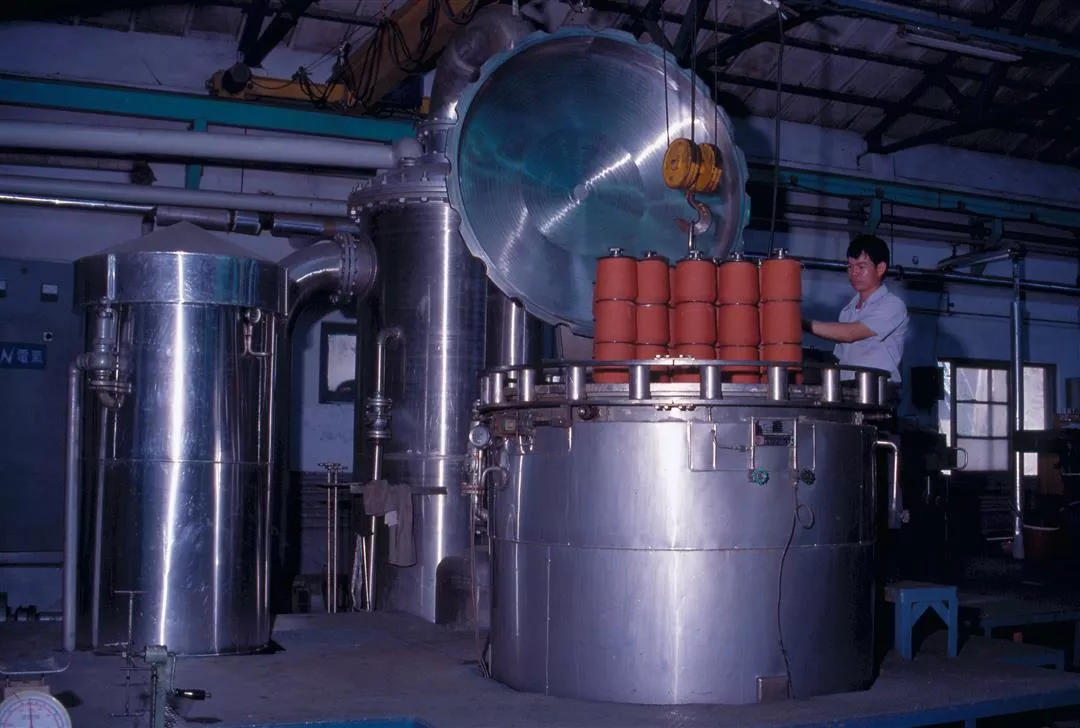

3. T'ai-yuan Textile's spherical warping device aids the work of making yarn.

Industry leaders still see a bright future.

Seaward's new weaving machines imported from Switzerland are fully automated;.

one worker can operate six at once.

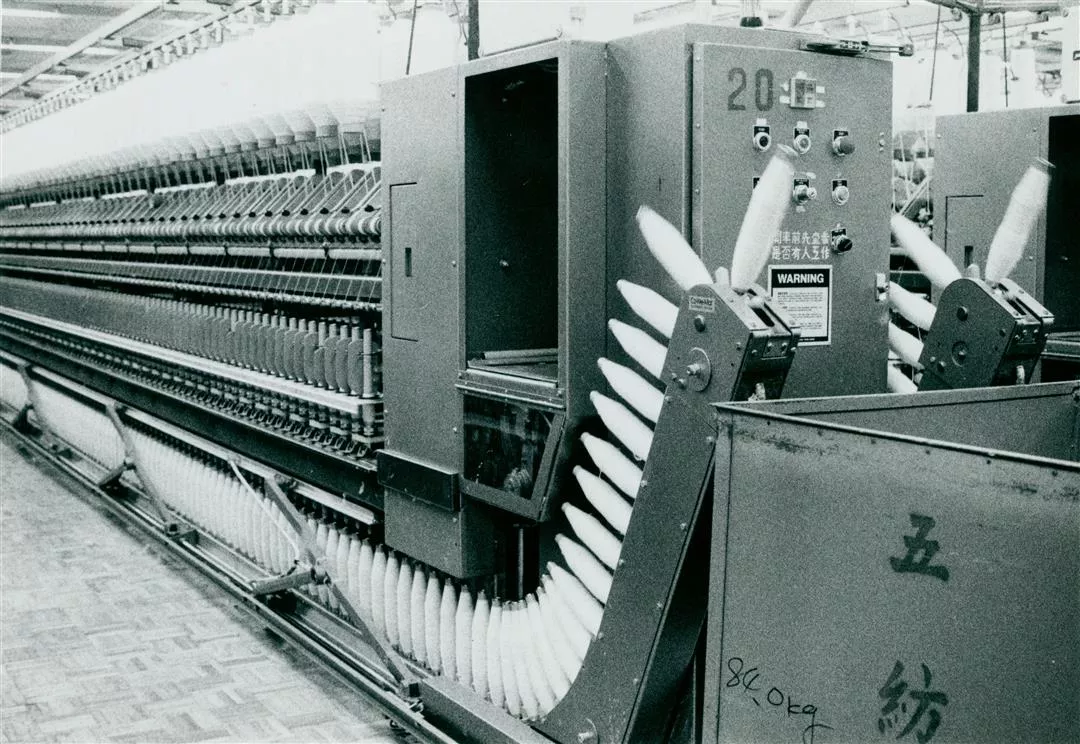

4.5. Automation almost eliminates the need for human supervision.

4.5. Automation almost eliminates the need for human supervision.

T'ai-yuan's process for making colored denim.

@List.jpg?w=522&h=410&mode=crop&format=webp&quality=80)