"The thing that makes Taiwaneses trong is combativeness. If we can just work together, nobody will be able to beat us!"

Back in the 1980s, when Taiwanese glass firms and their clients were moving in droves over to mainland China, "TMG" (which stands for both Taiwan Mirror Glass, the English name, and Tai Ming Giang, the name in Taiwanese), decided to stay in Taiwan. At the time the company's top man, Jackson Lin, vowed to form a strategic alliance with other firms and hold the line in Taiwan by fighting as a team. The facts have borne out that there is power in unity, as in recent years TMG has repeatedly defeated its competitors and even attracted upstream and downstream Taiwanese firms to come back home.

In 2005, the strategic-alliance partners formally created Team Taiwan Glass (TTG), moving toward independent branding. This "dream team" of more than 100 firms has an ambitious long-term goal: that one day people who hear the word "Taiwan" will think of glass, just like people who hear "Holland" think of tulips.

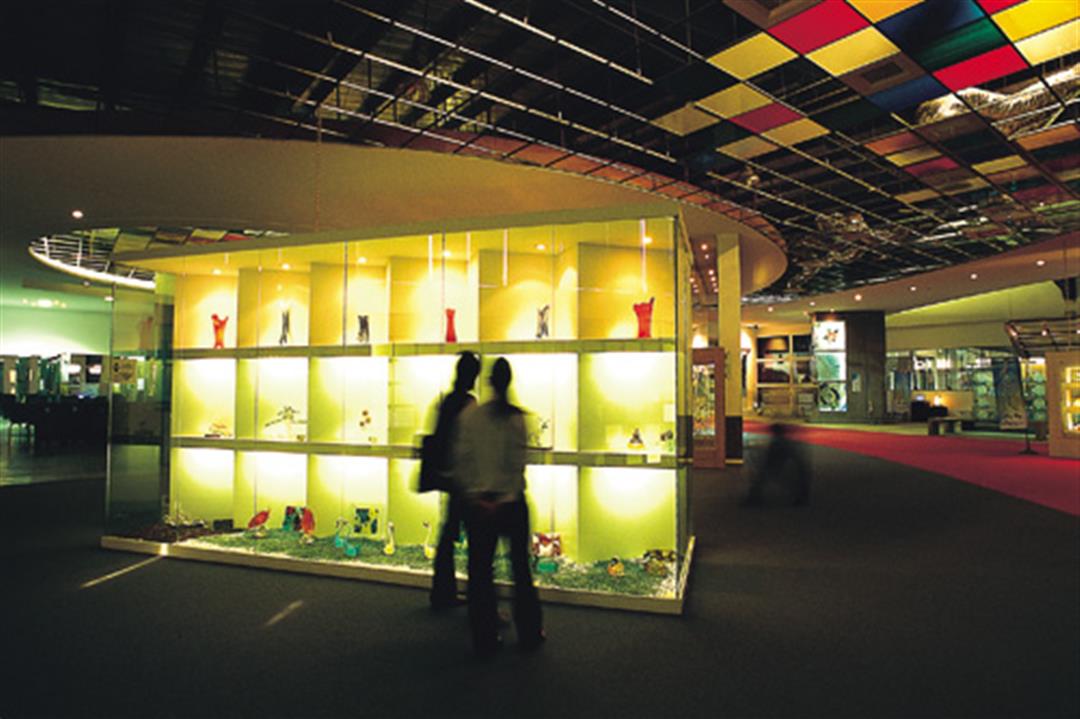

The Taiwan Glass Hall has over the past two years become a landmark in the Changhua Coastal Industrial Park. Not only is it as crowded as a market during the weekend, but even on weekdays there is a constant stream of tour buses filled with students on field trips, tourist groups, and even foreign dignitaries.

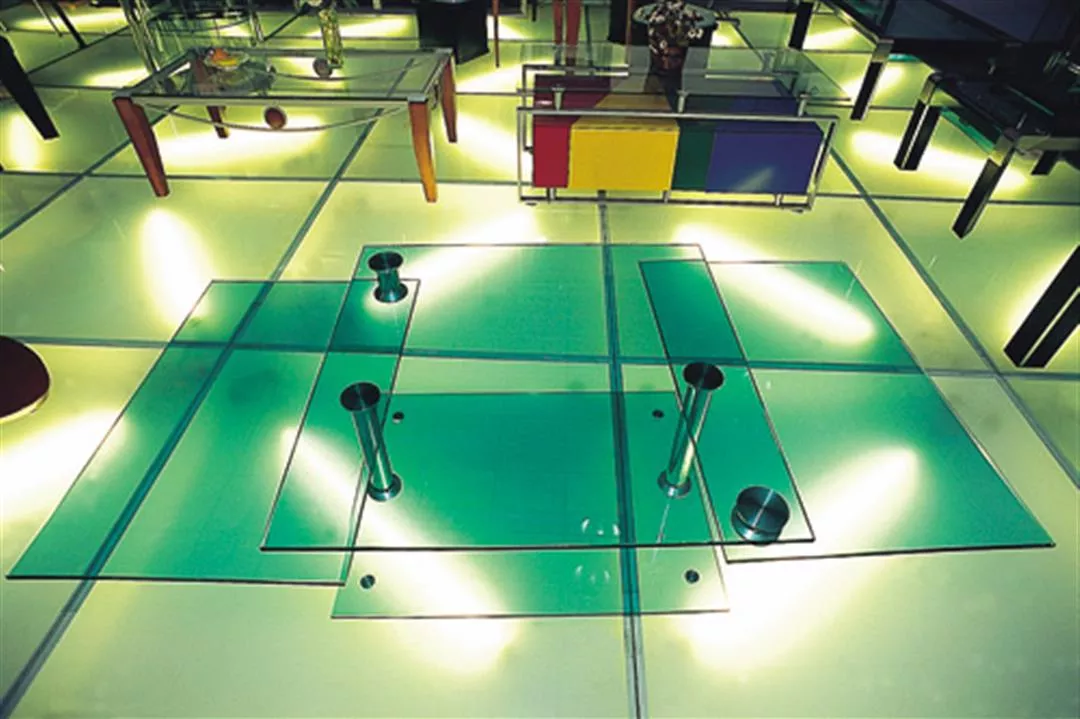

"This pane of glass is the largest in all of Taiwan; after being specially treated, it now has five times greater shock resistance; it can serve as a standing screen or room divider," intones the guide to her audience of more than 100 students and teachers as she stands before a wine-red glass wall three meters high and 12 meters long. Next the group passes through a corridor of colored glass, patterned after Lugang's "Chest Touching Lane," wide enough for only one person. When they reach the room exhibiting artistic glass creations, the kids, gasping in amazement, crowd round a glass sculpture of ants under a loofah trellis....

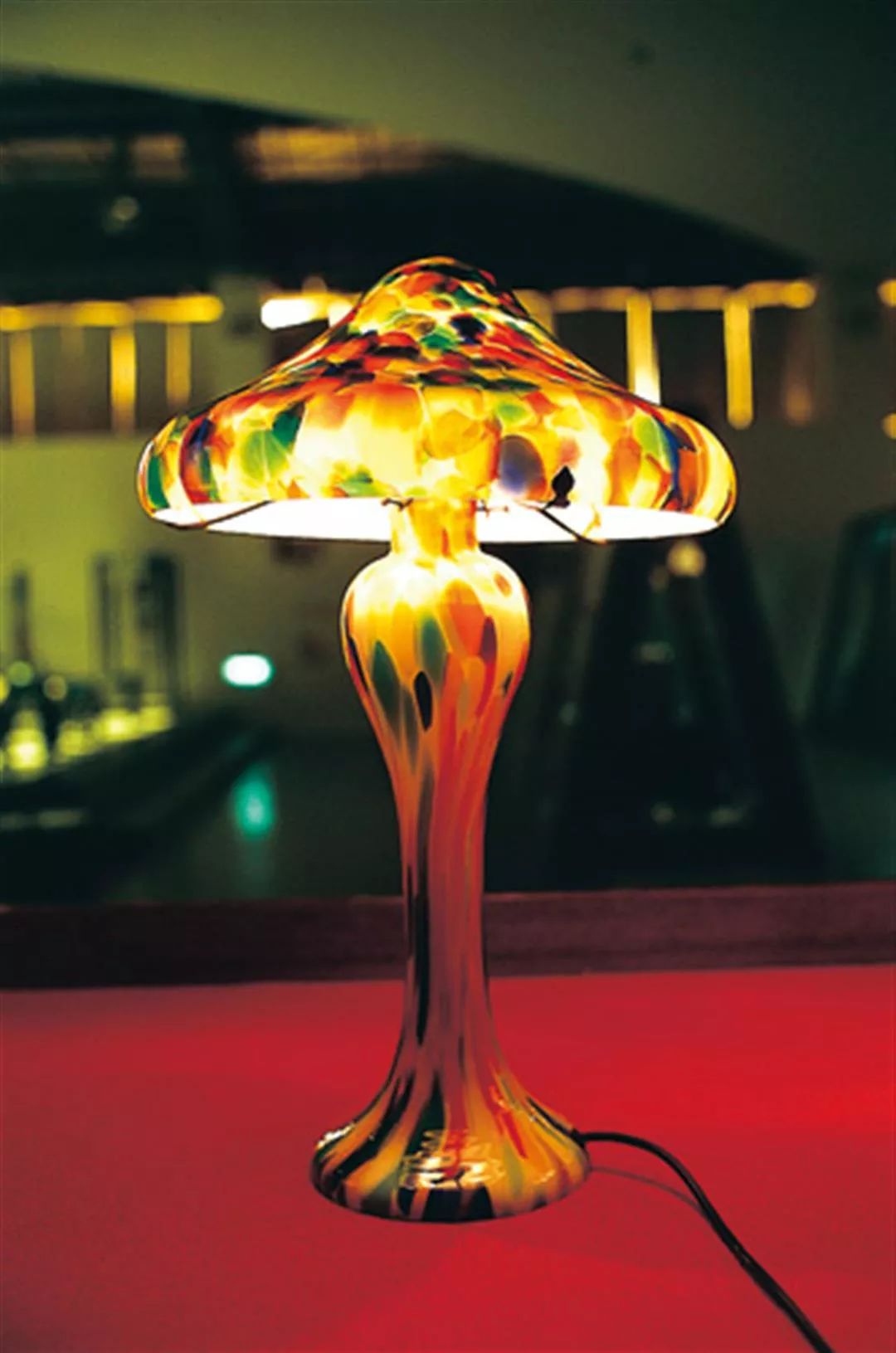

The Glass Hall, made out of TMG's former Lugang factory, exhibits over 10,000 items from more than 100 corporate members of "Team Taiwan Glass" (TTG). Unlike the Hsinchu Municipal Glass Museum, which is devoted to creative expression through glass, a turn round the hall in Lugang is a revelation in just how intimately intertwined glass is with our daily lives-from kitchenware, bedroom mirrors, living room bookcases, and bathroom counters to automobile headlights, appliances, lamps....

TMG general manager Jackson Lin, who founded the hall, relates that its original purpose was simply to provide "one-stop shopping" to foreign buyers. It became a tourist attraction only because back in 2006 the chief executive of Chiayi County invited the museum to open to the public as part of the Dragon-Boat Festival celebrations. They ended up drawing 50,000 visitors in nine days, and haven't closed their doors since!

The TTG group includes more than 100 glass-related firms,encompassing both core industries (like lighting, building materials,and engineering) and peripheral industries.

20 years to make a masterpiece

Lin, known to those in the business as "Elder Brother," traces the origins of TTG back to 1984. At that time traditional industrial firms were fleeing Taiwan, but Lin figured that if you moved every time land and labor costs rose, your firm would be fated to end up a "nomadic refugee." Seeing how countries like Switzerland with its watches and the Netherlands with its flowers had been able to make traditional industries sustainable, he was determined to do the same in Taiwan.

In order to survive, Lin began to promote collaboration in the glass industry. His logic was this: though any firm could expand facilities and manpower, the increased costs would add many new variables to operations, which small firms like TMG could not cope with. It was better, he concluded, to form strategic alliances. Besides spreading risk, this would also create flexibility and strength-"the scale of an elephant with the agility of a flea."

Over the next 20 years Lin took to the road, rushing hither and thither to keep up morale and commitment. For many years now, he has worked 16 hours a day, usually just falling asleep on the couch when he gets home. With a guiding spirit like this, TTG has come from an early period in which people took a wait-and-see attitude to steadily attracting firms to join.

In order to maintain loyalty to the collective good, Jackson Lin has deliberately decided not to compete for profits with other team members. "If a factory in the group has certain facilities, then TMG will not acquire similar equipment, and if another member can handle an order then TMG will not try to win the order."

In their second decade, having gotten orders from IKEA, the alliance took their organization one step further and expanded facilities and production capacity in the various firms.

Entering its third decade in 2005, the group formally created TTG, marking closer integration. Besides having more than ten types of firms directly related to the glass industry-such as engineering, interior design, and fixtures and furnishings-TTG also includes peripheral industries like plastics, metals, lumber, and paper. Handling 80% of IKEA's orders for glass furnishings and fixtures nearly every year, they not only are outcompeting the home factory in Sweden and factories in China, but have allowed Taiwan to retain its status as one of the main bastions of the global glass processing industry.

"We are certainly fast enough," says Lin, enumerating another of TTG's competitive advantages. For example, not long ago IKEA designers came to Taiwan with an idea for "super-white glass" that would reproduce the feeling of "the sun casting a delicate shadow of a tree on a window." TMG then began working with Founder Aluminum and Gin Jye Ming Glass Company, and within three days they had turned the idea into a sample. This impressed the designers from IKEA's headquarters and ensured that TTG would get the immense US$60 million order.

A lot of furniture includes parts made from a variety of materials, like glass, aluminum, steel, and wood. Members of TTG each bring their own expertise to the group, greatly increasing international competitiveness.

Order chameleon

Because the alliance includes many different types of firms, they can get orders through different channels. When the customer wants mainly glass, TMG will step up; for aluminum, Founder will grab the order; for steel-tube furniture, Paor Tsann Enterprise Company will take the lead. After the order is received the various firms will help each other out in terms of materials, skills, and production processes.

But what happens when they have to cut costs to win an order? Jackson Lin explains that each company will put their costs out on the table, without hiding anything, and then they will figure out a solution together. For instance, the market price for glass drilling was about NT$4 per hole. Lin asked whether it might be possible to get a drilling machine to do four holes at once, for the same NT$4 price. Gin Jye Ming figured out how to redesign their machines to reach the goal, thereby slashing costs by three-fourths. "Until this order [from IKEA] came in, they had lost money over the preceding six months. But now, only seven years after opening," says Lin with respect, "Gin Jye Ming is the fastest, cheapest glass-drilling plant in the world!"

Now, TTG members are working to go from pure OEM manufacturing to ODM, in order to increase the value-added content of goods.

TMG, located in the Changhua Coastal Industrial Park, has organized companies in the glass industry into "Team Taiwan Glass" (TTG). Not only have they wrought a miracle in stabilizing the glass industry cluster on Taiwan, they have even attracted some Taiwanese firms that had gone elsewhere to come back and reinvest. The heart and soul of TTG, Jackson Lin, is seated at center in the front row in this picture.

From OEM to ODM

Founder Aluminum was originally IKEA's supplier of aluminum home furnishings. No longer content to pick up the meager profits of manufacturing for others' labels, Founder came back to Taiwan from Shanghai in 2004 hoping to build on the power of Jackson Lin's group to transform itself. It has been nurturing designers and working with TTG members to improve production processes in order to win ODM orders.

"Having TTG's support behind us has been a big factor in getting ODM orders," says Founder general manager Window Lin. In 2006, IKEA took a fancy to a series of Founder's original designs, and signed a five-year product development contract. During this period, Founder gets a two-year production monopoly on any product that it designs in-house; only in the third year is IKEA permitted to open manufacturing to global bidding.

Paor Tsann, which specializes in steel-tube furniture, also hopes that the support of TTG will help speed their transformation. After returning to Taiwan in 2005, Paor Tsann began cooperating with college and university design programs, and began getting orders for ODM curio display stands and other items from Japanese firms like Muji and Mitsui. "Although we are not as close with TMG as Foundation or Gin Jye Ming, Chairman Lin doesn't give any less support, and treats us as one of the family," says Paor Tsann manager Wu Chang-chin.

After years of hard-won experience, TTG is now highly competitive in terms of price, quality, and speed, and orders have continually risen. Foundation has seen 30% annual sales growth since joining TTG, and TMG's orders from IKEA have gone from US$10 million in 2003 to US$50 million in 2008.

In addition, the well-known Japanese bathroom company Toto started orders to TTG in 2006 that are now up to US$7 million, while hypermarts like Costco, B&Q, and Carrefour, who previously bought mainly in China, have been bringing orders over to Taiwan. "Overall," says Jackson Lin, except for 2008 (as a result of the impact of the global economic crisis), "the group as a whole has had 15% growth per year."

TTG won a huge order from IKEA for "super-white glass" that would reproduce the feeling of sunlight casting the shadow of a tree over a window, after TTG was able to turn the concept into a sample product within three days. The photo shows the production line at the Gin Jye Ming glass processing plant.

What elder brother says, goes

Outsiders can't help asking, although orders have been on the rise, how can they keep all of the ever-increasing number of team members happy?

Lin explains that there are three levels to the group. The first consists of 15 core firms in the Changhua Coastal Industrial Park, the second of Central Taiwan firms within 72 kilometers, and the third of firms anywhere in Taiwan. If the first tier can handle an order, they get it; whatever they can't cope with goes to the second and third tiers.

"TTG is a fair and unselfish platform," says Foundation's Window Lin. Members really trust "Chairman Lin's" judgment, so they don't worry that some other guy is getting more, and they don't withhold raw materials from each other.

He says there are two reasons why firms can honestly work together through TTG: One is that the upstream supplier Taiwan Glass Industrial Corporation offers stable and transparent pricing of materials. The other is that Jackson Lin has earned the trust of downstream firms.

"Usually you have to pay up front when you get glass, but Chairman Lin lets us take materials on credit and pay when we get the money. He even built a huge warehouse to keep a supply of glass on hand," says Window Lin. It's not just talk that has kept more than 100 company bosses convinced.

"I'm proud to serve TTG," says Feng Zongqing, the head of design at TGA Glass Enterprise in Tainan. He joined TTG as an unpaid advisor because he was inspired by Lin's vision and willingness to sacrifice. "TMG covers all the costs of the Glass Hall alone, and at the 2008 furniture exhibition put up the money and manpower for 60 stands."

Perfect competition

The success of TTG has even impressed IKEA's 83-year-old founder Ingvar Kamprad, who came to Taiwan from Sweden in March 2008 to figure out how TTG was able to grow year after year while other Taiwanese traditional industries were surrendering to low-cost mainland competition.

Chu Chih-ning, an assistant professor in Chung Yuan Christian University's Business Administration Department who has followed TMG and TTG closely, says that Lin's selflessness and foresight stem from his grasp of the reality of perfect competition, which has enabled him to build long-term relationships of trust between group members. No one dares strike out on his own for fear of losing the support of the closely knit network.

"There are low barriers to entry in the glass processing industry, technology is transparent, and substitutability is high, so buyers are in a strong position to force suppliers to cut prices to the bone." Chu explains that this "perfect competition" means that survival is almost impossible without cooperation, which has been a powerful condition contributing to TTG's strength.

As Lin perceived, in a market of perfect competition, expanding one's own scale and swallowing up competitors is not the most efficient strategy. On the other hand, if each cooperating plant has room to maneuver and there is flexible negotiation, this gets the most out of group scale. You can see how efficient this has been for TMG, as over the last ten years revenues have increased by five times, but the number of employees has increased by only 10%.

Safe thru the storm

The advantages of TTG's organization have been especially obvious since the financial tsunami of 2008.

"No single tree among us is very large, but our 'forest' has a strong foundation, so we won't topple." Lin says that although orders have unavoidably been affected, no TTG member has laid off workers. Unless bosses engage in private financial speculation, all the members of the group should get through the storm OK.

What is most gratifying to Lin is that at first Taiwan Glass Industrial Corporation strongly opposed Lin's efforts to organize collaboration. They argued that glass is too fragile to move around from company to company, so it is not suited to a division of labor. But now that the effectiveness of collaboration is making itself obvious, Taiwan Glass-which had previously frozen all new investment in Taiwan-returned in 2005 to put over NT$2 billion into a new plant in the Changhua Coastal Industrial Park, and recently has even been talking about providing money to TTG to shore up its finances.

Collective branding

Lin says that TTG has two directions for the future: ODM on the one hand, plus R&D and design on the other, to build a "TTG" brand name.

"There's still a lot of room for development in the glass industry," says Feng Zongqing, who racked up six patents in six months at TGA Glass Enterprise. A lot of operators only need advice on identifying specific problems; then the possibilities for development will open up. Since joining TTG he has brought in a lot of research from the Industrial Technology Research Institute (ITRI) to help firms upgrade.

Lee Chein-dhau, a researcher in the Material & Chemical Research Laboratories at ITRI, says that ITRI's Glass Industy Promotion Project has helped over 135 firms in upgrading in the last three years, including materials development, production process improvements, and product and technical development. For example, it is helping TMG make high-grade construction glass out of recycled bottles. Though the project is still embryonic because of the high technical barriers, there is enormous potential because recyclables are low in cost and there is no similar technology anywhere else.

Over the last three years TTG has also actively participated in international industry fairs, generating name recognition. Lin knows that branding is a long road, but "it is dreams that make people great."

Having served as chairman of the management committee for the Tianhou Temple in Lugang, Lin quips that he "was sent by the deities to inspire people to dream." In fact, he is now building a temple made almost entirely of glass and built on environmental principles. The interior decor will be based on ideas gathered from throughout the glass industry.

Having wrought a miracle out of Taiwan's OEM glass industry, TTG now aims to fix an "equals" sign between "Taiwan" and "glass" in the minds of the world.

@List.jpg?w=522&h=410&mode=crop&format=webp&quality=80)