前途不在自己手裡?

劉中鴻以機械所推行多年的廠商生產自動化服務為例,以前台灣根本沒有自動化工程服務公司之類的中間廠商,機械所只得負起直接輔導各行各業廠商的重責。但全國製造業廠商總數達八萬家,機械所怎麼全力以赴,一年也頂多服務數百家,連百分之一的比例都達不到。現在機械所改以指導中間廠商為主,把他們當做種子師資,希望藉他們發揮槓桿效應,機械所則可以將省下的人力精力,投入難度更高、更有挑戰性的研發目標。

話說回來,雖然各所情況不同,但大體而言,工研院的收入中有不少是來自這種直接服務各個廠商的「工業服務」業務,這類服務以工研院的能力足可勝任愉快,工作人員又可直接感受到業者對他們的感謝,如今輔導中間廠商來分攤重擔,不啻是為自己製造競爭對手,因此員工對這種方案都不免有所疑懼。

「若是現有業務逐漸轉移出去,機械所本身的研發能力又沒有辦法『升級』,是會造成所內一千多名員工不知何去何從的困境」,劉中鴻坦承。只做研發及服務等公益事項而不能追求利潤的工研院,在既不得與民爭利,卻又必須朝自給自足、盈虧自負的目標努力,同時還要避免裁員壓力影響研發人員工作情緒等種種互相矛盾的要求下,工研人的彷徨,不難理解。

面對劇變中的產業環境及外界對工研院的諸多爭議期許,工研院的廿歲生日,需要深思,更需要鼓勵。

〔圖片說明〕

P.96

「ITRI」不僅是工研院的英文縮寫,加上「DE」,則代表它的六大信念--創新、團隊、互重、敬業、奉獻和卓越。

P.97

雖自嘲為「科學怪人」,但工研人的多才多藝,也是激發創意的一種途徑。

P.98

平靜而帶點單調,院區中少見人影走動,原本在大家都窩在各自的實驗室裡埋頭鑽研。

P.99

新近完成的國家級「次微米」實驗室,為國內第一座八吋晶圓積體電路示範廠,在無塵的要求下,工作人員需全副「武裝」才准近入。

P.99

外人常以為工研院必是男性天下,其女性員工比例達四分之一,通宵作實驗、或是下鄉訪視廠商,女性也不讓鬚眉。

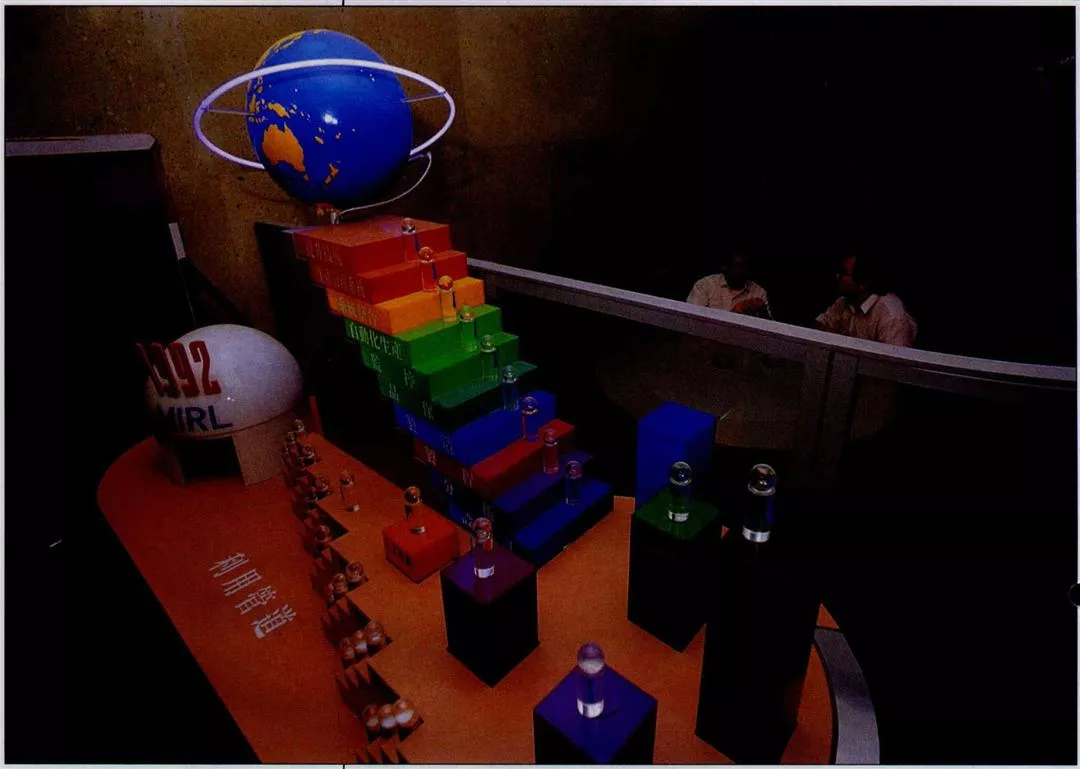

P.100

開發先近技術,協助傳統產業升級輔導中小廠商,工研院是國內八萬家製造業者的技術後勤支援單位。

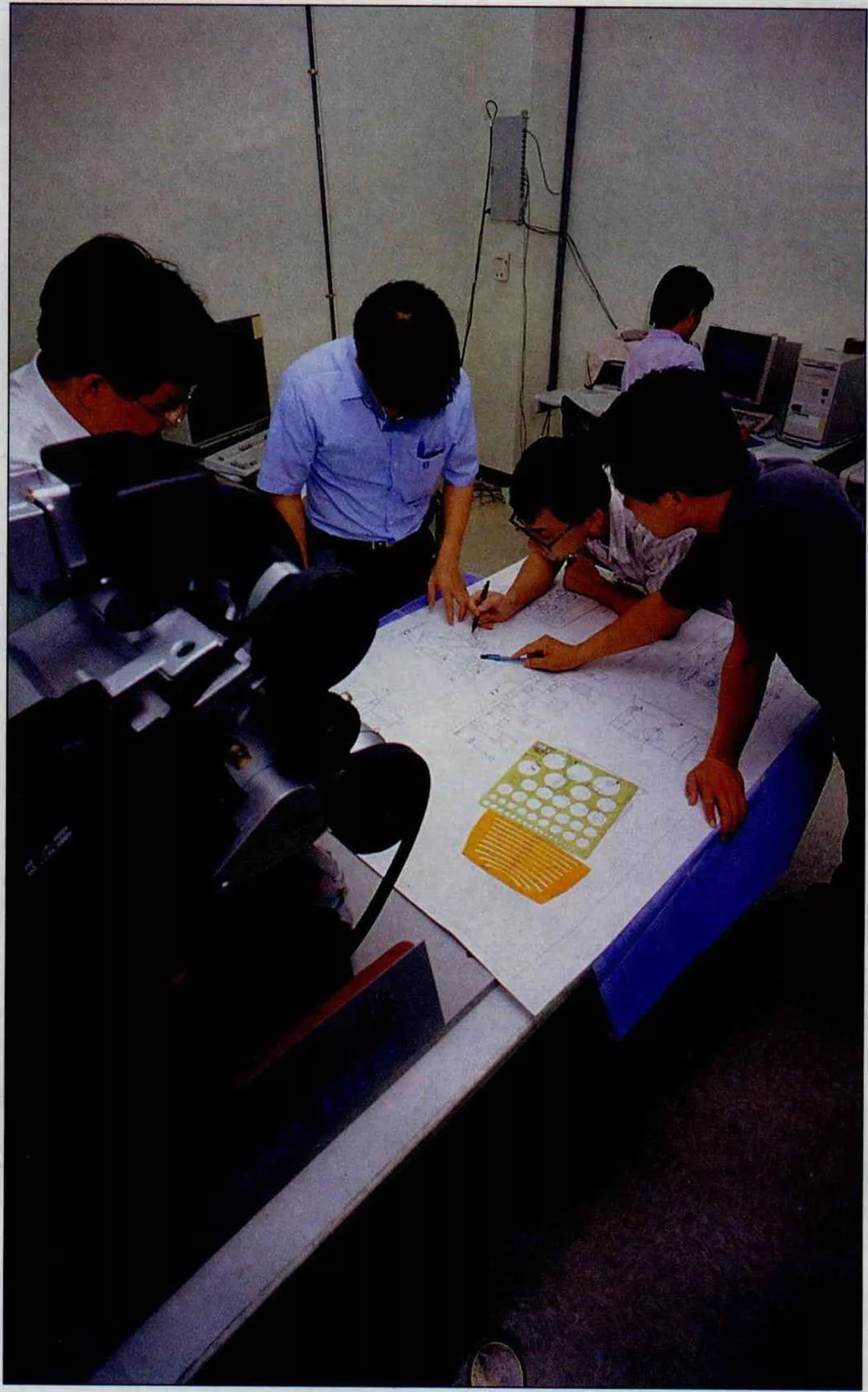

P.101

目前已近入第三年度的共同引擎開發,由工研院統合並引近英國蓮花汽車的技術,希望在中華民國加入「GATT」、進口車大舉入侵後,國產汽車還能有競爭能力。

P.102

埋首鑽研了一天,黃昏時刻出來舒散一下筋骨也好。

P.104

每天在台北、竹東間通勤往返的員工不在少數,為了求進步,車上的時間也不能輕易浪費。

開發先近技術,協助傳統產業升及輔導中小廠商,工研院是國內八萬家製造業者的技術後勤支援單位。

目前已近入第三年度的共同引擎開發,由工研院統合併引近英國蓮花汽車的技術,希望在中華民國加入「GATT」、近口車大舉入侵後,國產汽車還能有競爭能力。(薛繼光)

埋首鑽研了一天,黃昏時刻出來舒散一下筋骨也好。(薛繼光)